Welcome to the 2025 Guide on ISOBUS (ISO 11783)! This protocol simplifies data exchange in agriculture, allowing diverse equipment to communicate seamlessly. ISOBUS was developed to address the challenge of incompatible machinery interfaces, which greatly enhances efficiency and ease of use for farmers worldwide. Let's explore how it works.

ISOBUS is a vital communication protocol in agriculture, evolving from the SAE J1939 standard. It's integral for modern farming and forestry equipment, facilitating real-time communication and data analysis in tractors and other machinery.

Introduced in 2001, ISO 11783 has become a key standard for major manufacturers, ensuring equipment software compliance.

This guide is essential for anyone in agriculture seeking to optimize operations. It offers insights into selecting compatible equipment and understanding the benefits of data-driven farming.

Whether you're a farmer, technician, or manufacturer, this guide simplifies ISO 11783, aiding in modernizing agricultural practices.

What does ISOBUS stand for?

ISOBUS can be divided into two words: 1. ISO, and is an acronym for International Organization for Standardization, which is an indication of a global standard. 2. BUS, and it refers to the movement of data from one location to another.

What is ISOBUS?

ISOBUS, also known as ISO 11783, is a standardized communication protocol crucial in the agricultural and forestry sectors. It facilitates seamless interaction between tractors, various software, and equipment from major manufacturers. Here's a closer look at what ISOBUS entails:

-

Unified Communication: ISOBUS allows for the exchange of data and information in a universal language through a single control located in the tractor’s cab.

-

Centralized Control System: The tractor's cab transforms into a complex on-board computer, capable of controlling different tools and implements, ensuring real-time data interchange.

-

Interconnectivity: It enables the tractor's computer system to communicate with various implements, such as sprayers, seed drills, and plows, eliminating the need for separate computers for each implement.

ISOBUS significantly enhances the efficiency and functionality of modern farming and forestry operations, standardizing the way machinery communicates and operates. Here's some key features of ISOBUS:

-

Standardization: ISOBUS serves as a common standard for data transfer in agricultural and forestry machinery, identified as ISO 11783.

-

Interoperability: The protocol aims to establish interoperability and compatibility in data transmission among sensors, actuators, control units, memory, and display units in machinery.

-

Network Integration: It defines a serial data network for control and communications among different electronic control units (ECUs) in the vehicle’s network.

-

OSI Model Compliance: ISOBUS adheres to the Open System Interconnections (OSI) model, as specified in ISO 11783, for equipment in agriculture and forestry.

What is ISO 11783 standard?

The standard is an integral part of agricultural and forestry machinery, that establishes a serial data network for control and communication. It's primarily implemented through the ISOBUS software stack, a crucial element in modern farming technology.

-

ISOBUS Software Stack: This is a pre-packaged software solution developed in line with the ISO 11783 standard. It facilitates network connectivity between tractors and implement electronic control units (ECUs), enhancing communication and efficiency.

-

Inter-Vehicle Networking: The ISO 11783 standard enables efficient inter-vehicle network connections, streamlining interactions between various machinery components.

Additionally, ISO 11783 has its roots in the J1939 specifications, known for their extensive use in commercial vehicle applications:

-

J1939 Specifications: ISO 11783 is a derivative of these specifications, bringing their robustness and reliability to agricultural machinery.

-

CAN BUS Integration: J1939 encompasses the CAN BUS system, a resilient automotive bus standard. This system enables effective communication between on-board microcontrollers and various devices, significantly contributing to the functionality and performance of agricultural and forestry equipment.

In essence, the ISO 11783 standard is a cornerstone in the agricultural and forestry sectors, enhancing vehicle communication and operational efficiency through its comprehensive network and software solutions.

Key Layers of ISOBUS Stack Protocol

The ISOBUS stack protocol, aligned with the ISO 11783 standard, outlines a multi-layer framework for communication in agricultural and forestry equipment:

-

CAN Network: This is the physical layer where the actual transmission of data occurs. It refers to the Controller Area Network (CAN), which is a robust vehicle bus standard allowing microcontrollers and devices to communicate with each other without a host computer.

-

CAN HAL (Hardware Abstraction Layer): This layer serves as an intermediary between the raw hardware of the CAN Network and the higher-level software. It abstracts the details of the hardware, allowing the software above it to operate regardless of changes in the hardware.

-

Data Link (ISO11783-3): This is the protocol layer that controls the data exchange over the CAN network. It defines how messages are formatted and processed for transmission and how they are detected and retrieved by the receiving devices.

-

Network Management (ISO11783-5): This layer is responsible for managing the network, including addressing of devices, error handling, and ensuring that messages are correctly identified and routed to the appropriate devices.

-

Implement Message (ISO11783-7): Here, the standard specifies how implement messages, such as those from sensors or actuaries on a piece of equipment, are structured and transmitted over the network.

-

Diagnostic Services (ISO11783-12): This layer provides a set of diagnostic tools and messages that allow devices to report the health of the system, troubleshoot issues, and ensure that all components of the system are functioning correctly.

-

Task Controller (ISO11783-10): The task controller layer manages application-specific tasks. It controls the operations such as planting or harvesting by sending commands to implements and ensuring the tasks are carried out as instructed.

-

File Server (ISO11783-13): This layer handles the storage and retrieval of files, which may include maps, application rate tables, work records, and other data necessary for the operation of agricultural machinery.

-

Virtual Terminal (ISO11783-13): The virtual terminal serves as the user interface layer. It allows operators to interact with the ISOBUS system, input commands, and view system status and messages through a display in the tractor’s cab.

-

User Application: At the top of the stack, this is where the specific applications that the operator uses reside. These applications utilize all the layers below to perform complex tasks like monitoring and controlling machinery.

Each layer in the ISOBUS stack has specific roles and responsibilities, ensuring that different electronic components in agricultural and forestry machinery can communicate and operate harmoniously. The stack as a whole allows for the integration of a wide variety of equipment and software from different manufacturers, promoting efficiency and interoperability in the field.

The Complete 14-Part ISO 11783 Standard

The ISOBUS is a collection of protocols for electronic communication. Here's a brief overview of its 14 parts:

|

ISO 11783 Part

|

Description

|

|---|---|

| Part 1 | General Standards: Covers the basics of mobile data communication. |

| Part 2 | Physical Layer: Details the hardware and electrical aspects of the network. |

| Part 3 | Data Link Layer: Manages direct data transfer between connected devices. |

| Part 4 | Network Layer: Directs data within a larger network through routing and addressing. |

| Part 5 | Network Management: Ensures efficient network operations and coordination. |

| Part 6 | Virtual Terminal: Provides the user interface for interacting with the networked system. |

| Part 7 | Implement Messages: Standardizes communication specific to implements. |

| Part 8 | Power Train Messages: Focuses on communication related to the vehicle's powertrain. |

| Part 9 | Tractor ECU: Describes the electronic control unit within the tractor. |

| Part 10 | Task Controller: Manages agricultural tasks and data interchange. |

| Part 11 | Mobile Data Element Dictionary: Defines data elements for mobile applications. |

| Part 12 | Diagnostics Services: Offers tools for system diagnostics and maintenance. |

| Part 13 | File Server: Manages the storage and access of files within the network. |

| Part 14 | Sequence Control: Oversees the sequence of operations and control processes. |

How Does ISOBUS work?

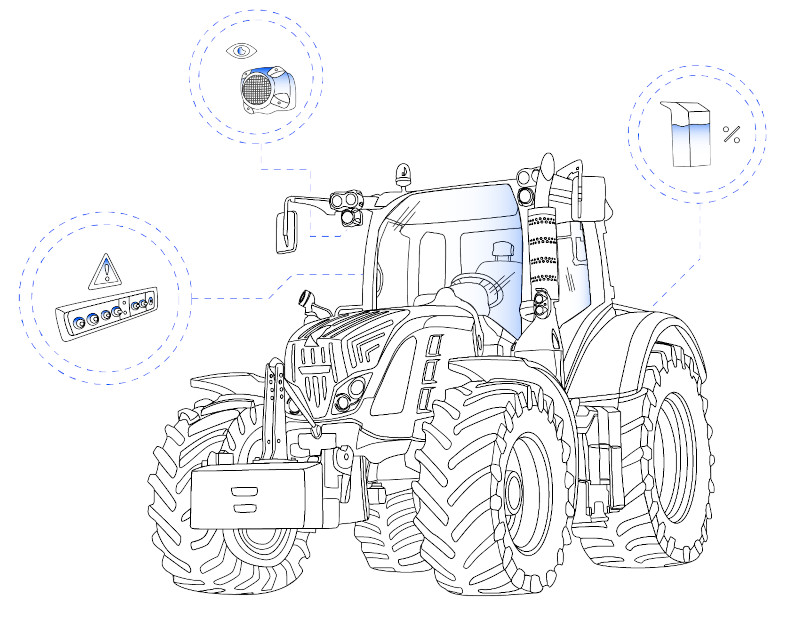

ISOBUS unites agricultural and forestry equipment through a common communication protocol. For instance, when a seed spreader is attached to a tractor, it's instantly recognized, and its operational data flows into the tractor's central ISOBUS controller.

The ISOBUS system's Core Elements:

-

Universal Terminal (UT): This component allows the tractor's display to operate any connected implement, regardless of manufacturer. For example, an operator can control a sprayer from one company and a harvester from another without needing separate monitors.

-

Task Controller (TC): This records detailed job data and supports task planning and monitoring. Imagine an operator spreading fertilizer; the TC can record the amount used per acre, adjusting rates on-the-fly for optimal crop yields.

ISOBUS eliminates the language barrier between devices, enabling seamless integration and data-driven decision-making in modern farming.

ISOBUS vs. CAN Bus

When delving into the realm of vehicle communication systems, particularly in the agricultural sector, two prominent protocols emerge: ISOBUS and CAN Bus. Though they share similarities, understanding their distinct functionalities and applications is crucial for any agricultural tech enthusiast or professional.

While CAN Bus provides the essential layer for data transmission and error checking, ISOBUS extends these capabilities with agriculture-specific features. Here’s what sets them apart:

-

Application: CAN Bus is a general-purpose protocol, whereas ISOBUS is dedicated to agricultural equipment interoperability.

-

Complexity: ISOBUS allows for more complex communication and control tasks tailored to the needs of farm machinery.

-

User Interface: ISOBUS includes a standardized user interface through the Virtual Terminal, which is not a concern of the CAN Bus protocol.

Choosing between ISOBUS and CAN Bus depends on the application. For general vehicle communication, CAN Bus is the go-to. However, for agricultural machinery and operations that require seamless integration and advanced control, ISOBUS is the clear choice. Understanding the specific needs of your operation is key to selecting the right protocol for optimal performance and efficiency.

Understanding ISOBUS Connectors: Pinout and Plug Details

ISOBUS connectors serve as the critical link between tractors and implements, ensuring clear communication through standardized pinouts and plugs. These connectors are designed to withstand the rigors of the agricultural environment, providing reliable connections that facilitate the transfer of power, data, and control signals across various equipment. Understanding the pinout configuration of ISOBUS connectors is essential for compatibility and troubleshooting in the field.

The Role of the ISOBUS Terminal in Agricultural equipment

The ISOBUS terminal, often referred to as the Virtual Terminal, is the interface that operators interact with. It's the central hub where data from various implements is displayed and controlled. This terminal allows for the monitoring and adjustment of implement settings, streamlining the operation process, and enabling precise control over complex farming tasks. The standardization of the ISOBUS terminal across different brands ensures a consistent and user-friendly experience for operators.

The Proven Advantages of Adopting ISOBUS

Embracing ISOBUS technology in agriculture and forestry significantly streamlines operations and enhances efficiency. Here’s how:

-

Unified Computer System: With ISOBUS, you only need one computer for your tractor, regardless of the equipment brand. This computer connects to any ISO 11783 compliant tractor through a plug-and-play ISOBUS connector pinout, eliminating the need for multiple computers.

-

Interoperability Across Brands: ISOBUS ensures seamless compatibility between tractors and implements of all brands and models, offering a diverse range of information and control.

-

Standardized Controls and Improved Visibility: It standardizes control settings, improves cabin visibility, and simplifies the connection process between tractors and implements. This not only enhances the user experience but also brings about significant cost savings when using multiple ISOBUS implements.

-

Efficient Monitoring and Data Analysis: From planting to harvest, ISOBUS facilitates variety monitoring, enabling the collection and precise analysis of data across different fields.

The six key benefits of ISOBUS include:

-

Simplified Control: A single display in the cab controls various tools and applications, regardless of the manufacturer.

-

Ease of Connection: The standardized nine-pin connector allows for easy connection of different equipment to your tractor.

-

Enhanced Data Transfer: Effortlessly transfer data between your PC and the tractor's display.

-

User-Friendly Interface: ISOBUS standardizes control settings, reduces downtime, minimizes installation issues, and eliminates the need for platform calibration.

-

Cost Efficiency: Only one display is needed for all types of equipment across different manufacturers.

-

Valuable Data Collection: ISOBUS plays a crucial role in creating precise farming documentation, aiding in the optimization of farming operations.

Adopting ISOBUS brings about a transformation in agricultural practices, marked by efficiency, compatibility, and insightful data management.

A Journey Through the History of ISOBUS

The development of ISOBUS marks a significant chapter in the evolution of agricultural technology. This journey, spanning over three decades, reflects a continuous effort to enhance communication and interoperability in agricultural machinery.

1991: The Genesis of ISOBUS: The journey began in 1991 when the International Organization for Standardization (ISO) set up an initial working group, SC19, also known as Working Group 1. This group's mandate was to develop a standardized communication protocol for agricultural equipment.

2001: Introduction of ISOBUS in Machinery: A decade later, in 2001, ISOBUS started to make its way into practical use. Tractors and implements began to incorporate this technology, marking a new era of connectivity and data exchange in agriculture.

2003-2005: Enhancing Interoperability through 'Plugfests': Between 2003 and 2005, significant strides were made in making ISOBUS increasingly interoperable. This period saw the introduction of 'plugfests', events where manufacturers tested the compatibility of their equipment with ISOBUS, ensuring seamless communication across various brands and models.

2008: Establishment of the AEF: In a move to further bolster the development and implementation of ISOBUS, the Agricultural Industry Electronics Foundation (AEF) was established in 2008. The AEF played a crucial role in setting standards and facilitating collaboration among different stakeholders in the agricultural electronics industry.

2022: Advent of High-Speed ISOBUS (HSI): The most recent milestone in the ISOBUS timeline occurred in 2022 when the AEF demonstrated the High-Speed ISOBUS (HSI) based on Ethernet technology. This advancement promised even greater speeds and efficiency in data transmission, opening new possibilities for smart farming solutions.

Through each of these milestones, ISOBUS has evolved to become a cornerstone of modern agricultural technology, significantly impacting the efficiency, productivity, and sustainability of farming operations worldwide. This journey through the history of ISOBUS not only highlights the technological advancements but also the collaborative efforts that have driven the agricultural industry forward.