As explained in our ultimate guide to CAN Bus, the Controller Area Network (CAN) is fundamental to the seamless operation of electronic components within modern vehicles.

In the telematics sector, the efficiency of CAN Bus systems is paramount, enabling the sophisticated functionalities that underpin today's automotive technology. However, the occurrence of CAN Bus errors can disrupt this intricate communication, resulting in operational inefficiencies and potential safety hazards.

For developers and telematics businesses, the ability to swiftly identify, understand, and rectify these errors is essential.

This guide is designed to provide you with comprehensive insights into detecting, diagnosing, and fixing CAN Bus errors, ensuring the reliability and performance of your telematics solutions.

This guide aims to equip you with the knowledge to detect, diagnose, and resolve CAN Bus errors, ensuring your systems operate at their peak performance. Let's get started.

What Causes CAN Bus Errors?

CAN Bus errors stem from a variety of issues that disrupt the normal communication flow between the network's electronic control units (ECUs). These errors can range from simple wiring problems to more complex protocol violations.

Understanding these causes is the first step toward effective troubleshooting and system maintenance.

Before we delve into the common causes of CAN Bus errors, it's essential to understand the types of errors that can occur on the network.

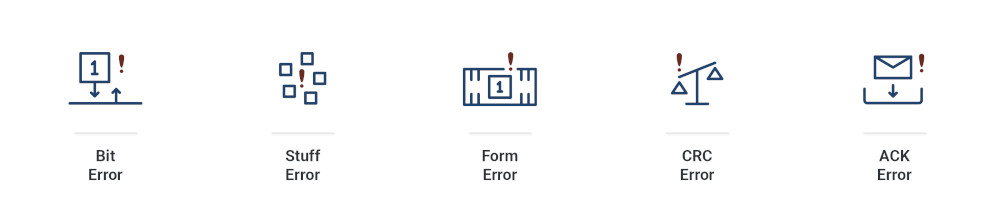

CAN Bus protocol defines several specific error types, each indicating a particular issue within the system. These include:

-

Bit Error: Occurs when a transmitting node detects a discrepancy between the transmitted bit and the bit received by another node. This error typically indicates a fault in the communication process, such as physical layer issues or electrical interferences.

-

Stuff Error: The CAN protocol uses a bit-stuffing technique to prevent errors during data transmission. A stuff error is detected when there are more than five consecutive bits of the same polarity, violating the bit-stuffing rule.

-

Form Error: This type of error is identified when a fixed format part of a message violates the expected format, such as issues with the frame boundary or the fixed fields within frames.

-

CRC Error: A Cyclic Redundancy Check (CRC) error occurs when the CRC sequence at the end of a message doesn't match the calculated value. This discrepancy suggests that the message has been corrupted during transmission.

-

ACK Error: An acknowledgment error arises when a message transmitted on the CAN Bus does not receive a positive acknowledgment from any other node, indicating that the message was not properly received by the network.

Understanding these error types is a critical first step in diagnosing and addressing CAN Bus errors. Now, let's explore the common causes behind these errors and how they can impact the communication within your telematics systems.

-

Physical Layer Issues: Faulty wiring, poor connections, or damaged cables can interfere with the CAN Bus signals. Physical disruptions like these are common sources of errors, as they can corrupt data being transmitted across the network.

-

Electrical Interferences: CAN Bus systems are designed to be resilient against noise. However, excessive electromagnetic interference (EMI) from external sources or other electronic systems within the vehicle can lead to signal degradation and errors.

-

Protocol Violations: The CAN Bus operates under a strict set of rules defined by its protocol. Any device that does not adhere to these rules can introduce errors. This includes incorrect message formatting, timing violations, or the transmission of erroneous data.

-

Overloaded Network: When too many messages are sent simultaneously, or a device monopolizes the bus, it can cause network congestion. This overload can result in delayed message transmission or, in severe cases, loss of data.

-

Faulty ECUs: Electronic control units that malfunction due to hardware failures or software bugs can send incorrect data or fail to communicate altogether, leading to errors within the CAN Bus system.

By recognizing these error types and their common causes, developers and professionals in the telematics field can take informed steps towards troubleshooting and resolving issues, ensuring the reliability and efficiency of their CAN Bus systems.

The AutoPi TMU device is a crucial component in modern telematics systems, facilitating seamless communication and data transmission across the CAN Bus network.

How Do You Detect and Diagnose CAN Bus Errors?

Detecting and diagnosing CAN Bus errors efficiently combines technical knowledge, practical skills, and the appropriate tools.

Below is an overview, structured to resemble a table format, detailing methods for identifying and analyzing CAN Bus errors:

|

Detection Method

|

Purpose

|

Tools

|

Notes

|

|---|---|---|---|

| Monitoring System Performance | To observe any signs of delayed message transmission or unexpected system behavior indicating potential errors. | Diagnostic software, system logs | Regular monitoring is crucial for early detection of issues. |

| Using Diagnostic Software | For logging and decoding messages on the network, highlighting error frames. | Specialized diagnostic software | Software tools provide insights into the network's health and error specifics. |

| Physical Inspection | To check for damaged wires, loose connections, and signs of wear. | Visual inspection, manual testing | Physical layer issues often manifest as visible damage or loose connections. |

| Oscilloscope Analysis | To inspect signal integrity and identify electrical interferences or signal level issues. | Oscilloscope | Essential for diagnosing electrical and physical layer issues not apparent through software. |

| Error Frame Analysis | Understanding specific error frames transmitted on the network to pinpoint errors. | Diagnostic tools, CAN protocol knowledge | Error frames offer direct clues to the nature and origin of problems. |

| Engaging with the Community | For troubleshooting uncommon issues through shared knowledge. | Online forums, professional networks | The collective knowledge of communities can provide additional insights and solutions. |

This approach to detecting and diagnosing CAN Bus errors emphasizes the importance of a comprehensive strategy, leveraging both sophisticated diagnostic tools and basic physical inspections.

By employing a variety of methods, developers and telematics professionals can ensure their systems remain operational and efficient, minimizing downtime and preventing potential system damage.

What Are the Best Practices for Troubleshooting and Preventing CAN Bus Errors?

Troubleshooting and preventing CAN Bus errors effectively is essential for the smooth operation of telematics systems.

Adhering to best practices not only mitigates the risk of errors but also ensures the robustness of your network.

A key tool in this endeavor is the AutoPi device, a versatile telematics unit powered by Raspberry Pi, which offers comprehensive capabilities for monitoring, diagnosing, and preventing CAN Bus errors.

Here’s how incorporating AutoPi and following strategic approaches can help maintain your CAN Bus system's integrity:

Understand Error Types and Causes

Familiarizing yourself with the various CAN Bus error types — Bit, Stuff, Form, CRC, and ACK errors — and their root causes is crucial for effective troubleshooting.

Regular System Monitoring with AutoPi

The AutoPi TMU CM4 is instrumental in continuously monitoring your CAN Bus system. It logs CAN messages in real-time, offering valuable insights into system performance and highlighting potential error precursors.

Diagnostic Checks with AutoPi

AutoPi shines in conducting diagnostic checks. It interfaces directly with the vehicle's ECU to extract error codes and status reports, simplifying the task of identifying issues within the CAN Bus system.

Physical and Electrical Inspection

Conduct routine inspections of the physical and electrical aspects of your CAN Bus network. Check for any signs of damage, loose connections, or wear. AutoPi aids in this process by monitoring electrical parameters that reflect the network's condition.

Firmware and Software Updates

Ensure that your AutoPi device and all components of the CAN Bus system are up to date with the latest firmware and software versions. These updates often address known bugs and enhance system stability.

Develop a Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your CAN Bus system, utilizing AutoPi to automate diagnostic checks and set reminders. Regular maintenance is key to addressing issues proactively.

Support and Help from AutoPi Professionals

The AutoPi team consists of experienced professionals ready to assist with troubleshooting and preventive advice.

Their expert support can provide tailored solutions and insights, leveraging their deep understanding of CAN Bus systems and the AutoPi device.

Incorporating these best practices, along with leveraging the AutoPi device, enables developers and telematics professionals to effectively manage CAN Bus errors.

The AutoPi device not only facilitates early detection and diagnosis but also supports comprehensive preventive measures, ensuring the reliability and efficiency of telematics systems.

Key Takeaway

Throughout this guide, we've explored the intricacies of CAN Bus errors, their causes, and the methodologies for detecting, diagnosing, and resolving these issues.

By understanding the types of errors that can occur and employing a comprehensive strategy for monitoring and maintenance, developers and telematics professionals can significantly enhance the reliability and performance of their systems.

The integration of the AutoPi device into your troubleshooting and preventive maintenance routines offers a technological edge, enabling more efficient monitoring, diagnosis, and resolution of CAN Bus errors.

The capabilities of AutoPi, combined with a thorough understanding of CAN Bus systems and adherence to best practices, form a solid foundation for minimizing the impact of these errors.

Remember, the key to managing CAN Bus errors effectively lies in:

-

Continuous learning and staying updated with the latest advancements in CAN Bus technology.

-

Regularly monitoring and maintaining your systems to catch and address issues before they escalate.

-

Leveraging technology like the AutoPi device to streamline diagnostics and preventive measures.

-

Seeking support and guidance from experienced professionals, especially the knowledgeable AutoPi team, to enhance your troubleshooting strategies.

CAN Bus errors, while challenging, are not insurmountable. With the right tools, knowledge, and approach, you can maintain a high level of system integrity and performance.

We encourage you to stay proactive in your efforts to understand and mitigate CAN Bus errors, ensuring your telematics systems remain at the forefront of automotive technology and innovation.

If you want to know more about the AutoPi device or need assistance in optimizing your CAN Bus system, feel free to contact us. Our team of experts is always ready to provide support and guidance tailored to your needs.